Rubber to Metal Bonding, A Versatile Process

Rubber in its different forms demonstrates the ability to bond to all kinds of metals. And bonded rubber is stronger. Rubber to metal bonding is a means by which rubber is mechanically bonded to a metal insert during the moulding process. Typical applications for rubber to metal bonding include, any part requiring the combination of the flexibility of rubber and the stability of a metal.

You may have observed that manufacturers across many industries rely on rubber to metal bonding for their components. This is because rubber not only produces a very strong bond on metal, but it also can be used to combine several components into a single assembly. Automotive and industrial manufacturers increasingly are turning to rubber to metal technology to reduce their raw number of components, eliminate vibration and improve the performance of individual components and sub-assemblies used in harsh environment applications.

Examples of Rubber-Metal bonded include small mounts for motors to large locomotive suspension parts, parts used for the isolation of noise and vibration in automotive and engineering applications, larger components designed to decouple translational movement for bridges and buildings.

Rubber-Metal Bonding Process

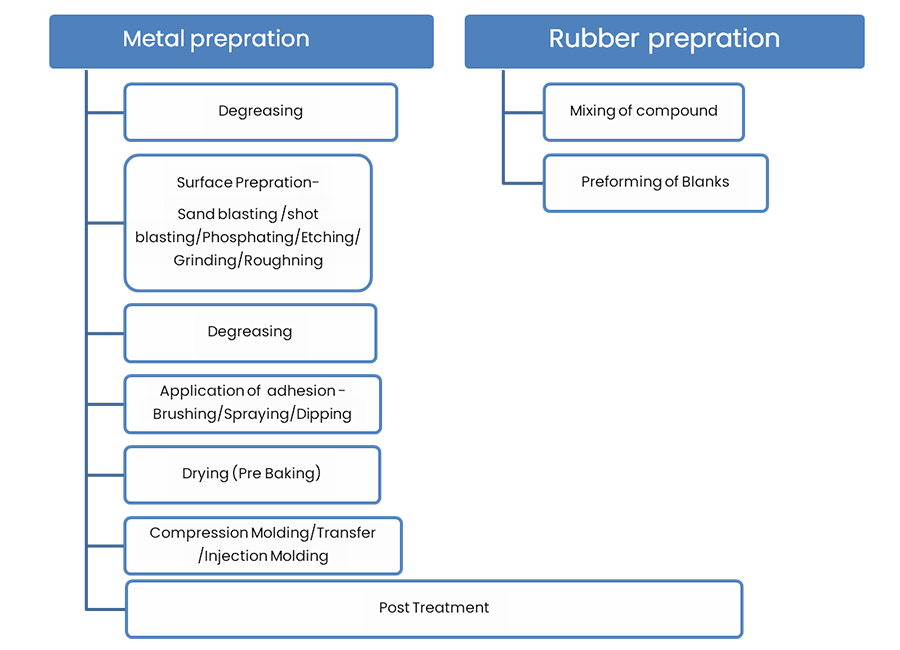

Briefly, the Rubber-Metal bonding process begins with the inserts that are first prepared for production using a grease removing system to rid your parts of any contaminants before the adhesive is applied. Subsequently, the heated adhesive is applied on to the inserts using a technique similar to your spray painting. Once the metals are prepared, the inserts are then physically placed, one at a time, into each cavity of your mold. Next, the rubber moulding process is started using the appropriate rubber moulding machinery. After the mold is closed, and the moulding begins, the adhesive on the metals is activated, allowing the inserts to bond to the rubber.

Steps to Effective Rubber-Metal Bonding

The scope of the following discussion limits only to bonds formed with metal parts while the rubber undergoes vulcanization. This does not cover bonding of vulcanizates with metals at the raw stage or after curing is completed.

Whatever your application may require, we can permanently bond molded rubber components to many materials and substrates such as rubber-to-metal bonding (Steel, Mild steel, aluminum, brass & casting) or rubber-to-plastic bonding ( Teflon treated, nylon ) bonding.

Applications range from bonding natural , Nitrile, EPDM, SBR, Silicone, NBR/PVC, Polyurethane & viton to metals like steel , brass, casting and aluminum. Components ranging in size from small mounts to large locomotive suspension parts are just a sampling of rubber to metal bonded parts produced using this process by SRKP