Material Specification

Process Requirement

- Homogeneous mixing (Incorporation, dispersion, distribution and plasticization)

- Viscosity/process safety (ML1+4, MS)

- Stickiness and Tackiness

- Shaping (Calendaring, Extrusion, Assembling and Molding)

Compound property Requirement

- Hardness

- Stress-Strain properties (TS, EB, M-100, M-300, Tear)

- Abrasion resistance

- Hysteresis & Set properties

- Resistance to cut growth, fatigue, flex cracking

Resistance to Degradation

- Heat, Oxygen, Ozone

- Flame

- Liquids

- Light

- Metal poisoning

Miscellaneous property requirements

- Low temperature flexibility

- Electrical properties

- Permeability

- Contact with food stuff and drugs

- Bonding to metal & textiles

- Swelling

- Other specific requirements

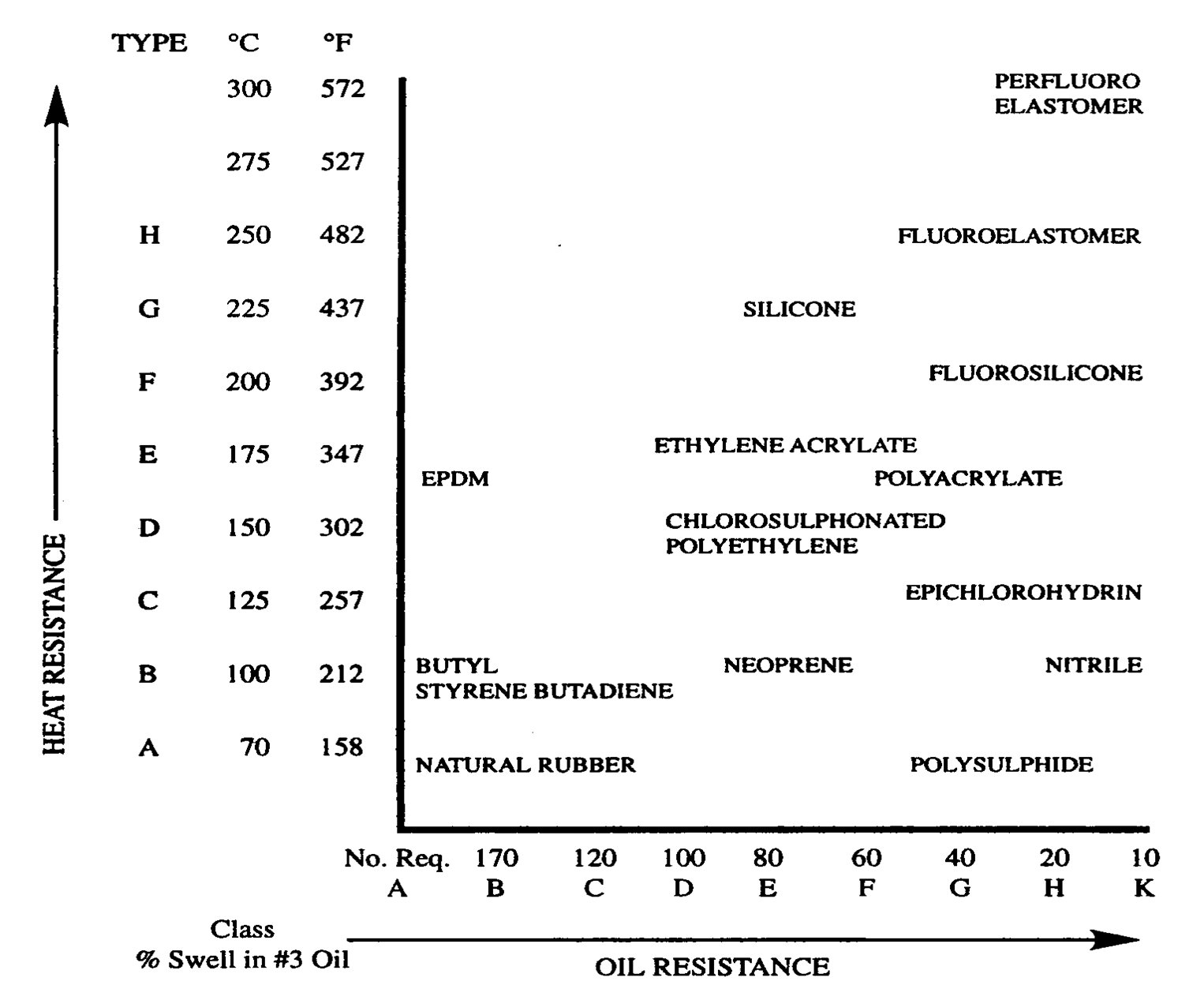

Relative Oil & Heat Resistance of Various Elastomers