Testing

SRKP uses the latest equipment and technology for testing of raw materials, compounds and the finished products. We have a laboratory that is very well equipped and our chemists and engineers have extensive academic and practical knowledge and experience in the rubber industry. The following are the key areas under testing

- Quality of Incoming Materials

- Quality of compound & In-process Materials

- Quality of finished products

- Compounding Development

- Product performance testing

- HIPOT Testing/Di-Electric Testing

Testing in SRKP

Raw Material Testing Internal & External

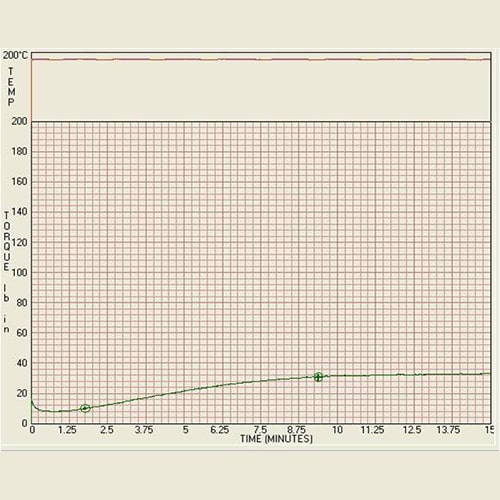

Mooney viscosity test-Internal

-

Type of samplesRaw polymer , Un-vulcanized Compound

-

ASTM StandardsD1646, D3346

-

SignificanceThis test gives an idea about the processing characteristics and correlation between viscosity value and molecular mass. This test also gives an idea about the processing safety of the compound

Melting point test-Internal

-

Type of samplesChemicals

-

ASTM StandardsD1519

-

SignificanceThis test helps to check the purity of the chemicals and also the processing characteristics of the chemicals

DBP Absorption test-Internal

-

Type of samplesCarbon Black

-

ASTM StandardsD2414

-

SignificanceThis test indicates the structure of the black, this test gives an idea about the processing and vulcanizing characteristics of blacks

Aniline point test-Internal

-

Type of samplesProcessing Oils

-

ASTM StandardsD611

-

SignificanceThis test indicates the Aromaticity of the processing oils. This is an important properties of oils for selecting in compound development

Solubility test-Internal

-

Type of samplesChemicals, Fillers

-

ASTM StandardsD4578, D4315, D4934

-

SignificanceThis test indicates about the percent impurities

Ash content test-Internal

-

Type of samplesRaw polymer, Chemicals, Fillers, Finished Product

-

ASTM StandardsD297, D1506, D4574

-

SignificanceThis test indicates the percent inorganic impurities in the sample. This may vary with respect to color of compound & Polymer

Sieve residue test-External

-

Type of samplesChemicals, Fillers

-

ASTM StandardsD1512, D4572, D5461, D4315

-

SignificanceThis test indicates the aggregate size of powdery materials. This test also indicates the distribution of powdery materials in the compound

Miscellaneous Test for Raw materials-External

| Chemical Properties | Type of samples | ASTM Standards | Significance |

|---|---|---|---|

| Heat loss | Carbon black, antioxidants, zinc oxide | D1509, D4571 | This test indicates the low boiling organic materials |

| PH value | Carbon black, silica, clay, latex | D1512, D1417 | This test indicates the acidity/alkalinity of the materials |

| Surface area | Carbon black, silica, zinc oxide | D4820 | This test indicates the available surface area of the materials for interaction with the rubber molecule |

Compound testing Internal & External

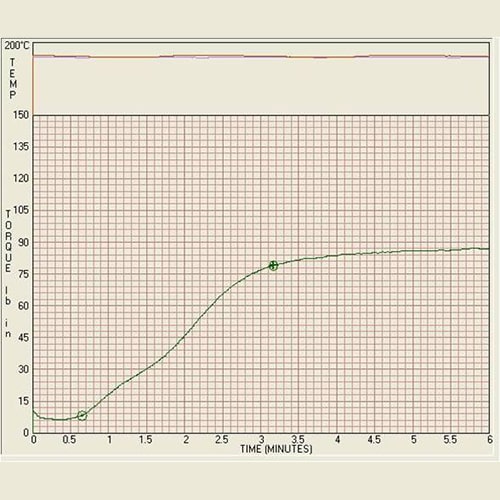

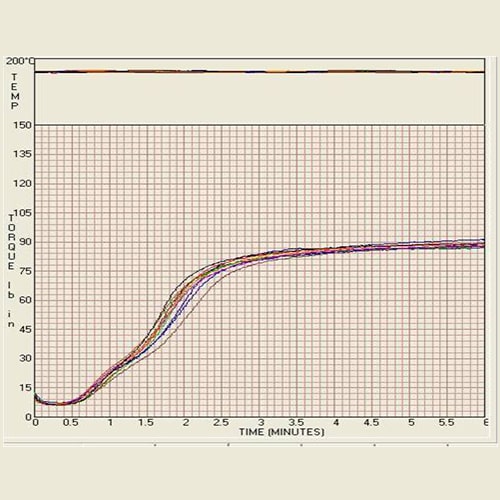

Vulcanizing characteristics test-Internal

-

Type of samplesUn-vulcanized Compound

-

ASTM StandardsD2084, D5289

-

SignificanceThis test gives an idea about the rate of cure, maximum torque of the compound with a particular curing system.

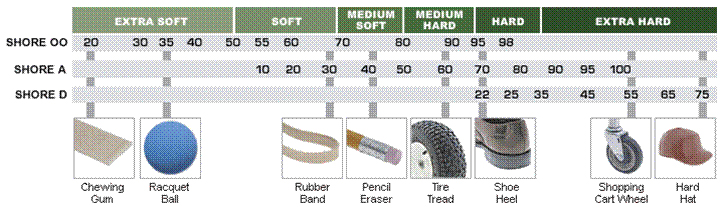

Shore A Hardness test-Internal

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD2240, D1415

-

SignificanceThis test gives an idea about the degree of curing.

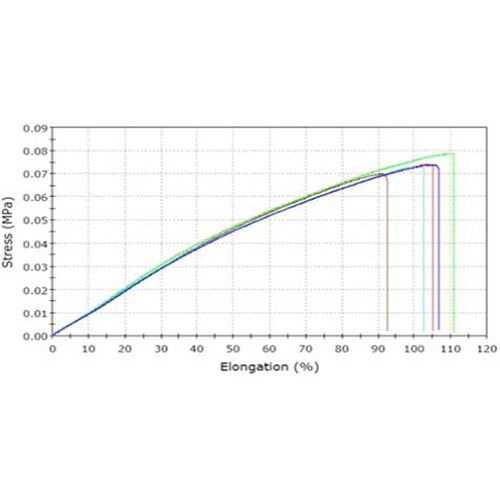

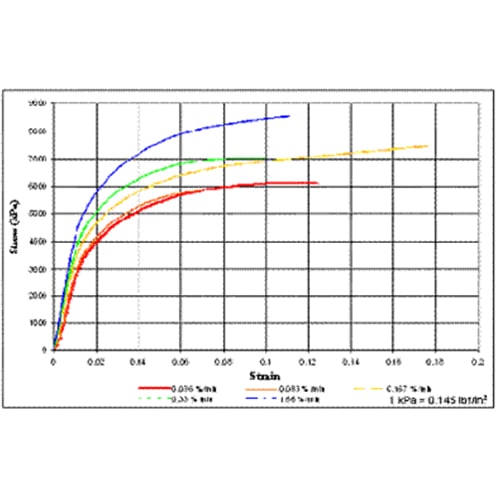

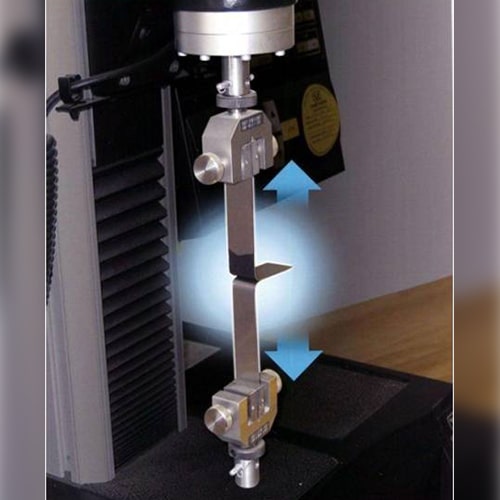

Tensile strength & elongation at break test-Internal

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD412, D624

-

SignificanceThis test gives an idea about the state of cure, This test also gives information regarding the uniformity of the product

Compression set test-Internal

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD395

-

SignificanceIt measures the retention of elastic properties of vulcanized rubber compound

Specific gravity test-Internal

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD297

-

SignificanceThis is a quick method of checking the weighing error during mixing. This test also gives an idea about the consistency of batches

Ageing properties test-Internal

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD856

-

SignificanceThis test indicates the degradation of the vulcanized rubber under accelerated condition. This test also helps the Compound to predict the compound properties suitability in a particular application

Resilience test-External

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD2632

-

SignificanceResilience is a function of both dynamic modulus and internal friction of a rubber, percent resilience of a rubber compound is an indication of hysterisis energy loss

Abrasion test-External

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD5936, D1630, D2228

-

SignificanceThis test gives an indication of wear properties of the vulcanized rubber, for tyre it gives direct idea about mileage

Ozone resistance test-External

-

Type of samplesVulcanized Rubber

-

ASTM StandardsD1149, D3395

-

SignificanceThis is another degradation test to find out the characteristic of the vulcanized rubber compound in ozone atmosphere.

Miscellaneous test for compound-External

| Physical Properties | Type of Samples | ASTM Standards | Significance |

|---|---|---|---|

| Low temperature resistance | Rubber Compound | D832 | With standing temperature of compound |

| Fuel resistance | Rubber Compound | D471 | Swelling percentage of rubber |

| Flex cracking | Rubber Compound | D813 | Crack resistance of compound |

| Water resistance | Rubber Compound | D6284 | Swelling of compound with eater |

Finished product testing Internal & External

Di-Electric resistance test-Internal

-

Type of samplesRubber Product

-

ASTM StandardsD4496

-

SignificanceConductivity of the product

Bonding strength test-Internal

-

Type of samplesRubber to Metal Bonded Product

-

ASTM StandardsD905

-

SignificanceBonding strength of the product

Polymer identification test-External

Pyrolysis test

-

Type of samplesRubber Product

-

ASTM StandardsD7579

-

SignificanceTo identify the NR ,SBR & CR polymer

FTIR Test

-

Type of samplesRubber Product

-

ASTM StandardsD6348

-

SignificanceTo identify the polymers

Leakage test-External

-

Type of samplesOil Seals

-

ASTM StandardsF2786

-

SignificanceTo ensure the leakage of oil seals

Flammability test-External

-

Type of samplesRubber Product

-

ASTM StandardsE2058

-

SignificanceTo verify the extent of flame resistance of the product

Shelf Life of Rubber Products

Storage conditions are important for product usage after longer storing. Ageing effect continues even at room temperature even though very slow.

Hence it is advised to store the rubber product away from heat, Sunlight & moisture, preferably covered with black poly. Contact with grease, solvent, oil etc. should be strictly avoided.

Also FIFO system and storage stack height / rotation should be followed if stored for longer time to avoid any de-shaping.

Shelf Life of Rubber Products

| S.No | Rubber Type | ASTM Designation | Shelf life (Years) |

|---|---|---|---|

| 1 | Nitrile Butadiene Rubber | NBR | Up to 5 |

| 2 | Polyisoprene | NR/IR | Up to 2 |

| 3 | Styrene | SBR | Up to 3 |

| 4 | Ethylene propylene | EPDM/EPM | Up to 7 |

| 5 | Chloroprene | CR | Up to 10 |

| 6 | Polyurethane | EU | Up to 10 |

| 7 | Fluorocarbon | FKM | Up to 20 |

| 8 | Silicone | Q | Up to 20 |

| 9 | Fluorosilicone | FVMQ | Up to 20 |

| 10 | Polyacrylic | ACM/ANM | Up to 20 |