Miscellaneous test for compound-External

| Physical Properties | Type of Samples | ASTM Standards | Significance |

|---|---|---|---|

| Low temperature resistance | Rubber Compound | D832 | With standing temperature of compound |

| Fuel resistance | Rubber Compound | D471 | Swelling percentage of rubber |

| Flex cracking | Rubber Compound | D813 | Crack resistance of compound |

| Water resistance | Rubber Compound | D6284 | Swelling of compound with eater |

Finished product testing Internal & External

Di-Electric resistance test-Internal

-

Type of samplesRubber Product

-

ASTM StandardsD4496

-

SignificanceConductivity of the product

Bonding strength test-Internal

-

Type of samplesRubber to Metal Bonded Product

-

ASTM StandardsD905

-

SignificanceBonding strength of the product

Polymer identification test-External

Pyrolysis test

-

Type of samplesRubber Product

-

ASTM StandardsD7579

-

SignificanceTo identify the NR ,SBR & CR polymer

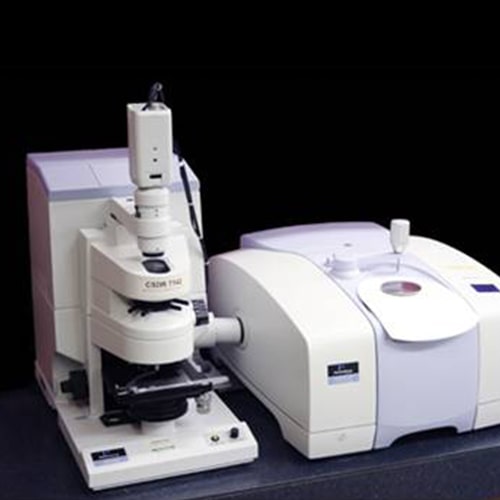

FTIR Test

-

Type of samplesRubber Product

-

ASTM StandardsD6348

-

SignificanceTo identify the polymers

Leakage test-External

-

Type of samplesOil Seals

-

ASTM StandardsF2786

-

SignificanceTo ensure the leakage of oil seals

Flammability test-External

-

Type of samplesRubber Product

-

ASTM StandardsE2058

-

SignificanceTo verify the extent of flame resistance of the product

Shelf Life of Rubber Products

Storage conditions are important for product usage after longer storing. Ageing effect continues even at room temperature even though very slow.

Hence it is advised to store the rubber product away from heat, Sunlight & moisture, preferably covered with black poly. Contact with grease, solvent, oil etc. should be strictly avoided.

Also FIFO system and storage stack height / rotation should be followed if stored for longer time to avoid any de-shaping.

Shelf Life of Rubber Products

| S.No | Rubber Type | ASTM Designation | Shelf life (Years) |

|---|---|---|---|

| 1 | Nitrile Butadiene Rubber | NBR | Up to 5 |

| 2 | Polyisoprene | NR/IR | Up to 2 |

| 3 | Styrene | SBR | Up to 3 |

| 4 | Ethylene propylene | EPDM/EPM | Up to 7 |

| 5 | Chloroprene | CR | Up to 10 |

| 6 | Polyurethane | EU | Up to 10 |

| 7 | Fluorocarbon | FKM | Up to 20 |

| 8 | Silicone | Q | Up to 20 |

| 9 | Fluorosilicone | FVMQ | Up to 20 |

| 10 | Polyacrylic | ACM/ANM | Up to 20 |